Ep. 21: Panic from Coronavirus Part 2 - John Sacco

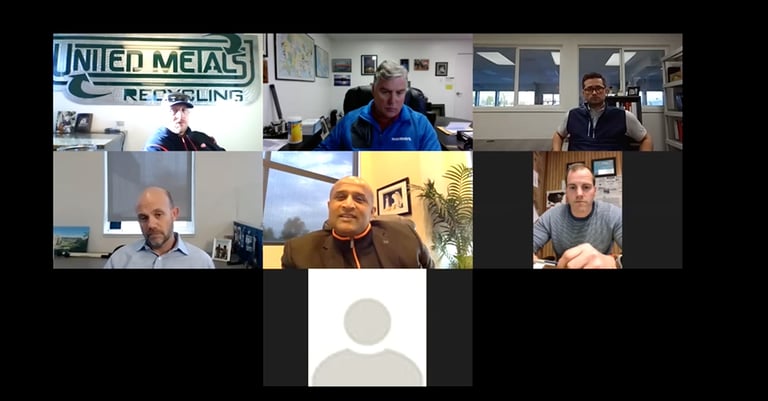

As we get more and more emerged into the Coronavirus pandemic, there are many questions being asked within the scrap industry. John Sacco invites medical professional Dr. Vip Dev and the biggest names in scrap such as Brett Ekart from United Metals Recycling, Sean Daoud from PNW Metal Recycling, Matt Kripke from Kripke Enterprises, Andrew Lincoln from Lincoln Recycling, and Nathan Frankel from Advanced Steel Recovery to give us the inside scoop on the availability of virus testing and how the scrap industry remains in operation through the slowing of production and business closures.

The Pile of Scrap Podcast is available on Apple Podcasts, Spotify, and Google Play. Be sure to Subscribe, Rate, and Review Pile of Scrap.

Watch this episode of Pile of Scrap here.

Top Row from Right: Brett Ekart, John Sacco, Sean Daoud. Middle Row from Right: Matt Kripke, Dr. Vip Dev, Andrew Lincoln. Bottom: Nathan Frankel was unable to join by video.

Transcription:

Intro: The following is an original audio series from Sierra International Machinery. Pile of Scrap with your host, John Sacco.

John Sacco: Morning.

Sean Daoud: Hey, John.

Matt Kripke: Hey, John.

John: Hey, Matt. How you guys doing?

Matt: Good. Hi, Sean, how you doing?

Sean: Good, Matt. How are you?

John: I'm doing great. Doing good, doing real good. Thank God. Knock on a little wood. You know, my daughter's home from Europe, so, uh, that's, uh, that's – that's always a good thing.

Matt: When did she get home?

John: Uh, Friday. So, she's been self-quarantining and, um, our, um, little beach house over in Carpinteria and, uh, she feels great. Um, she told me and Monica last night that she, uh, she loves it and she doesn't want us to come over. She's perfectly happy being alone right now and she's taken this so very serious – the, um, the things we're supposed to be doing – the social distancing, the this, the that. So, uh, it's good. Vip, how are ya?

Brett Ekart: What’s going on, guys?

John: Hi, Brett. How are ya?

Brett: I'm living the dream, man.

Dr. Vip Dev: Morning, guys.

John: Uh, the gentleman with a black, uh, jacket. That's Dr. Dev. Um, we, uh, we only have, uh, Andrew Lincoln to join. So, uh, why don't you go around, introduce yourself. Starting with you, Brett.

Brett: Uh, Brett Ekart, United Metals Recycling in, uh, Boise, Idaho today.

John: Matt.

Matt: Matt Kripke, Kripke Enterprises in Toledo, Ohio.

John: Sean.

Sean: Sean Daoud, PNW Metal Recycling in Portland, Oregon.

John: Vip.

Vip: Vip Dev. I'm a plastic reconstructive surgeon, but I run the Accountability Care Organization for Dignity Health in California, and, uh, we've got about 45,000 lives and about 800 physicians.

John: So, um, wait. Wait – we're waiting for Andrew, uh, Lincoln to join us, gentlemen. You know… There he is. Drew, how are ya?

Andrew Lincoln: Hey, John.

John: Hey. Um, all right, Drew, you just joined. Um, introduce yourself to everybody who you are and where you're at.

Andrew: Uh, hi. I'm Andrew Lincoln from Lincoln Recycling. We're based out of, uh, Northwest Pennsylvania, Eerie, Pennsylvania if you’re familiar with that. And, uh, I'm currently the, uh, ISRI, uh, Pittsburgh Chapter President as well.

John: Thank you, Andrew. And, then I see Nathan is joining. Nathan, are you there?

Nathan Frankel: Yeah, I'm here. Nice to join you guys.

John: Oh, I'm not seeing the video yet of ya.

Nathan: Okay, hopefully it'll come in. I'm in the car. Unfortunately, that's where I'm stuck. So, if you don't mind video from the car, I'll try to start it up.

John: No. Uh, so, um, Nathan, introduce yourself to everybody.

Nathan: Nathan Frankel. I operate a Scrap Metal Company in Fontana, California as well as trading company for containerized exports from the U.S. to, mostly, the Pacific Rim.

John: Okay. Uh, again, last – we'll go real quick around the horn one more time. Everybody, uh, Brad, again, starting with you.

Brett: Brett Ekart, United Metals, Boise, Idaho.

John: Sean.

Sean Daoud: Sean Daoud, PNW Metal Recycling, Portland, Oregon.

John: Matt.

Matt: Matt Kripke, Kripke Enterprises, Toledo, Ohio.

John: Vip.

Vip: Vip Dev, Bakersfield, California.

John: Dr. Dev. Andrew, one more time.

Andrew: Andrew Lincoln, Lincoln Recycling, Eerie, Pennsylvania.

John: All right, thank you everybody. Listen, you know, we – we've seen everybody's – seen messages about what everybody's doing, you know, with the distance – businesses is doing to – is that you moving around? It gets a little, uh – Nathan, if you're on cell, go to mute just because you won't hear the movement sound. All right. And, I wanted to take this conversation to a completely different, uh, direction from what our businesses are doing to protect our employees and protect – because I think everybody out there – is we’re doing way beyond that. And now, we're going into the phase of the economic impact, uh, and the movement and I wanted to have Dr. Dev with us because, you know, he's on the cutting edge of understanding what's going on and Dr. Dev.

Vip: Yeah.

John: Good friend of mine. He's in YPO with me, he’s in my forum group. Matt. Matt’s a YPO-er too. Anybody else in YPO on this group? Sean, are you? Not yet. You're too young to do YPO.

Sean: Somewhat of a YPO.

John: Okay. So, anyway, Vip, if you would, why don't you give us a quick up-to-date, if you can, on what the situation is and what's going on that you, in your understanding, and then we're hearing about: Uh, maybe the malaria drug is helpful. What are – what are you hearing today, Vip?

Vip: Yeah, yeah. So, uh, so if we look at the latest statistics, I mean, I – you know, I think it's important to address those. So, because everyone's got concerns, those numbers are rising and they are true. Those numbers are rising, but the testing has also gotten better since it first began to now. And, we have more availability of the test kits. So, as the availability of test kits becomes easier, you're going to see more detection of the disease process. That doesn't mean that you're seeing people actually get sick. Now, the age to remember worldwide right now is 20 and older. Um, those are the people that are being hospitalized, being treated, and then recovered. The people that are being hospitalized and being put in a critical situation, and the ones that are 80, 85 and older, not recovering – that's a substantial population. Uh, actually 20 – 20+ percent, but then the rest of them are 65 to 84 and younger and a lot of those are recovering. So, you're looking at about 80% of the people that get it, recover. So, those numbers there are very good, if you look at it from that perspective. Worldwide, you have about 230,000 cases and just under 10,000 deaths. About 90,000 of those patients have recovered so far as of this morning. So, we're getting data almost instantaneously, uh, on this disease process, which is really unheard of in our – in our world so far because this is the first time that's happened since the AIDS epidemic, right? That we're able to have this kind of data. The Spanish Flu, the Swine Flu, SARS. This, by the way, if you hear, if any of you hear SARS when they talk about Coronavirus, it's because it's in the same family of disease processes.

John: Alright, so Dev, Dr. Dev… the – what about them treatments, so far, on the Malaria drug? What are we hearing?

Vip: Yeah, so, um, you know, the chloroquine is, um – has been studied. Uh, I think we have to wait for actual true data to come out. Now, it sounds crazy that I talk about data coming out because we don't have that kind of time, but in reality, we do because we don't want people to get a false sense of hope with the treatment. If you have the active virus, uh – in India, they actually had a patient admitted and they used retroviral drugs to treat this patient and the patient recovered. What I mean by re–retroviral drugs is, because this is an RNA virus. So, I'm not asking all of you to remember your science from back in the day, but this is an RNA virus, which means a retroviral therapy could actually work on it. And, they used four different retroviral drugs in India and it did work on a patient. So, there is hope that there is going to be a long-term treatment for this disease process. Chloroquine, which is a Malaria treating, uh, medication has been known to work. But, I think the data still has to be proven whether or not it is, uh, it is going to work in the general population. If that's the case, it's a tabloid.

John: All right, well thank you. All right. Listen, just remember, everybody, this conference is being recorded. It'll be – I’m gonna introduce it as another episode of Pile of Scrap in a –in a different way. So, it is being recorded and it'll be put out there. Alright so, that said, Brett Ekart, you were one of the – the people I talked about in regards to what you wanted to hear. And, I got people from around the U.S, uh, assembled here. Matt, aluminum, uh, Andrew from the Eerie PA, the Eastern U.S, Nathan who handles shipping mega containers of scrap. Brett, I'll lead it off with you. What are you, um, you know, questions, and what's going on in your area and how it's affecting the movement of the recyclables and what – what's going on in your area?

Brett: No, I don't – I don't have a ton of questions per se, as much as I just want to focus the attention back to movement of scrap and our industry. And, I mean, I appreciate wholeheartedly, um, Dr. Dev’s opinion because, I mean, it's good to hear from a medical professional, not somebody spouting some bullshit on Facebook or some other website. Um, that has a ton of value to me, um, just to hear somebody like real talk about it. Um, I am just more focused on inter living. In Idaho, we're – we're kind of a – we're a pretty right-leaning state and we have a hard time people telling us what to do and how to do stuff. So, I mean, over here, the gyms are still open, the restaurants are still open now. I'll be it. I mean, I went to gym this morning, it was a ghost town in there. I think there was eight, 10 people in there. Um, but, uh, the restaurants are slow. So, I mean it is definitely, the effect is still there. I mean, my kids have been home now all week, you know, they're on spring break next week. So, it's more just for us, the movement of scrap, uh, making sure that you're steel mills and your shredder operators like Sean and those guys are, you know, open to buying scrap, receiving scrap, um, guys like Nathan that are, you know, moving containers. I mean, it sounds like that equipment's getting harder and harder to get every day. So, that's what I'm – that's really what I'm the most interested in.

John: Nathan, why don't you jump in? Okay, Dr. Dev, go ahead, and then Nate, I'd like for you.

Vip: Sorry, John. But, you know, Brett, your, your point is incredibly valid because, uh, John and I are in Bakersfield, California, you're in Boise. We're kind of very similar in our makeup and I think what you bring out is a very, very important topic for all the panelists to keep in mind. I think where you're located predicates what behavior you're seeing.

Brett: Right.

Vip: And uh, um, so in Bakersfield, you know, I – we go out and have beer. I did yesterday. You know, I mean it's different because we know who our contacts are because of the size of the city that we live in. Uh, so I think that's very important, but it's also important for employees to know that because that's what's going to really regulate our businesses, right? ‘Cause I – I'm a physician, but I'm also a businessman and I think that that is very important. So, it's what we actually teach our employees internally about the communication and their interactions with others, I think, is what's gonna really help us down the line.

John: All right, Nathan, right before you go, I want to make a point. Our peddler business is dramatically down right now. Industrial: Nothing changed. Peddler: way down. Nathan, why don't you give us an update on Pacific Rim, what you're hearing, movement of containers and what you're seeing out there in the market since you’re…

Nathan: Okay.

John: Nathan is, uh, for everybody's information – full transparency, Sierra sells Nathan a lot of tonnage, uh, and we have for years and Nathan as brokered our tonnage of iron, uh, like I said, for years and with success and Nathan, go ahead.

Nathan: Okay, I'm trying to make sure you all can hear me. I'm on my cell phone.

John: Yeah, I can hear you loud and clear.

Nathan: Okay, great. Yeah, I think the movement of scrap is obviously of paramount importance. We see two fundamental questions from all of our customers, which sounds obvious on the outset. The movement of scrap, “Can I get containers and what's the price?” The container availability and, even with respect to break bulk availability, is largely driven by what occurred in China several months back as those freights are primarily driven by the imports from China. So, obvious to say, that the ability to ship has been hampered by virtue of the fact that inbound imports were severely restricted. As China and most of North Asia and with South Asia being less affected by this as they are now reporting lower numbers and even yesterday I read a report saying China reported the first day without any numbers of increases, we think that the availability of containers and that bottleneck should have presented its worst case. But, the other factor is pricing. And, a lot of people – my experience, when they're in uncharted territory as we are now, people want to speculate and I think that does the greatest damage to the potential prospects of not only our ability to ship, but to try to keep the price volatility at a minimum. What I mean by that is I'll find, in any market change, I'll find people surface that think for whatever reason they can out-bet the market, they can catch the bottom. You know, catching the falling sword is impossible to do anywhere and it's not an exception in the scrap business. So, I tell my customers, focus on the fact that this is a supply side shock. Uh, not necessarily a demand side shock. And with that, count on the demand for scrap being there, but don't speculate and try to take advantage of some guy that walks in your office who you've never heard of before with a suitcase full of cash because he intends to take advantage of a potentially rising market and put a bunch of cargo on the water without a contract. That's what creates the volatility, that cargo ends up getting closer and closer to Asia without a contract. And, then all of a sudden it goes from a speculative move to address sale. And so, to keep that volatility at bay, I try to tell people, you're going to get the containers. That should probably ease up as far as an inhibiting factor, but you don't want to guarantee yourself future volatility by supporting a system that is purely speculative. Sell to a guy that you know has an order. And if he's not willing to be transparent about it, sell to a guy that's at least been in the business for more than 24 hours, and those bits of advice tend to smooth out volatility when times are uncertain.

John: Well, for full transparency here, uh, today I as I drove in our yard, Nathan, there's six containers. We're getting containers. Nathan has, you know, as our orders – we're getting containers. So Nathan, with all your customers that you're brokering out, uh, you okay getting containers? I mean, we're getting all the containers in our order.

Nathan: Yeah. Well, we love you and we treat you very well, but yes, we are. Uh, we are able to get containers and again, it's because we're trying to plan long-term and not – or some kind of immediate, quick speculated decision. So, it doesn't hurt that we've been shipping containers for the better part of 16 years. Um, it doesn't hurt that we have deep, longstanding relationships directly with steamship lines and not freight forwarders and brokers – freight brokers. But more importantly we've got bookings that go out months in advance and we tried to have the absolute lowest rate of cancellations. You know, again, just consistency, non-speculative. And, so that's allowing us to be, you know, one of the first guys in line to get that rare booking. But again, I think that issue of container availability is going to ease as things hopefully continue there. They're very early trend of normalizing in, in North Asia. Thank you. I hope that continues. I guess I do have, I do have one question back to the doctor.

Vip: Sure.

Nathan: Um, we hear about this, no new cases in China. What, in your opinion, is the chance – are the chances of this virus sparking back up a repeated hotspot in a previously known area?

Vip: Yeah.

Nathan: Can a person get it twice?

Vip: Yeah. Nathan, that's a great question. And here's my – here's a surveillance, uh, answer. Part of this is, if you notice, there are no new cases in China right now, and the ones that have had recent, uh, recent upstart in China have been people that have brought it back in. And so I think what it's going to take is, is it's going to take the country, uh, China and the surrounding countries to regulate the travel across and the testing. So, as a testing kits become readily available, easily available, and the rapid test becomes available, you'll be able to let people go back and back and forth across borders and get them rapidly tested so they can enter, but there's going to be a waiting period before they get back in because you can give them the result, you know, that they're not bringing that disease back in. So, to your point, Nathan, is that, uh, it's still a concern and I'm very concerned about it because our country survives on travel and, uh, China's one thing, but the United States is another. And so, we're really going to have to be very, very careful about the way we, uh, get back to our normal lives, which is why, I think, if I had to predict why the President's acted the way he has recently on the wartime acts, because it's really going to have to – we're going to have to control our travel ban really, really heavily to make sure that we don't get another spark in, uh, an increase in cases.

Nathan: But, is it known if a single person can get it twice? Or do you become somewhat immune to it?

Vip: So, you can become reinfected. Remember, what happens with the first time you get it, the biggest thing, uh, gentlemen, that I want you all to remember is Pulmonary Disease. What happens is, our lungs are like a big balloon and the more it expands, the better it is. What happens with this disease is the lungs get fibrotic and they get scarred down and they don't stretch. And if the lungs don't stretch, you don't exchange oxygen. If you don't exchange oxygen, that's when problems happen. And so, that's where we're seeing the biggest complications.

John: So, have we seen a repeat case, Doctor?

Vip: So, we haven't seen a repeat case. But, we don't know of those cases in China – of those deaths that happened in China – what they really were. A lot of those were initial deaths and that's what we're seeing. I don't think we're seeing any, uh, repeat infections that, uh, caused death because those people are detected early and the treatment of ventilation is early. So, the lung keeps expanding and the richer blood supply to the lung keeps it from scarring down after.

John: All right, I want to shift gears from scrap iron real quick. Sean and Andrew, I'm going to get to you, but I want to go to the aluminum world. Matt, um, you know, that's your – that's the world you live in. What's going on in that area from domestic and international? What's going on, Matt?

Matt: Uh, domestically, everyone that we shipped to is still taking deliveries, is still looking for deliveries. We had an interesting reaction. We called one of our consumers that we shipped two out of our processing facility, uh, here in Toledo and we said, “Hey, to protect our workers, we're going from, uh, 27 to 30 people working out back to nine. So, therefore, we're cutting our production, you know, significantly. And, we know we owe you a lot of material and we are going to, um, we'll honor the orders, but we have to slow down for a while. We're just not going to be able to make all the product for you that you were expecting.” And, I kind of expected him to say, “Unprecedented times. We understand. No problem.” His response was, “I need that metal. You gotta deliver. I need it. You're going to shut us – you're going to shut us down.” Um, it is automotive related with yesterday's news of the big three shutting down. I'm wondering how far along that is going to, uh – the dominoes are going to hit, um – or, the dominoes are going to fall. In terms of this part of the country – in terms of trucking, where my logistics team is telling me that rates are up, uh, about 33%. Um, we're hearing reports that there's a number of trucks that are, uh, a number of trucking companies that have taken their drivers completely off the road. And, uh, you know, you just take 15% out of the normal flow and you can figure what that is doing to rates and scrap is always the least desirable item that truckers want to take anyway. So, those are kind of the, uh, the quick summaries that we're seeing here in the Midwest. Um, I anticipate this is just me. I anticipate that with the big three shutting down, we're going to see domino effects in our industry domestically over the next week that we're going to start to see a lot of our consuming mills announcing they are going to shut down for a time to protect their workers. And, the reality is, a lot of them supply automotive and they'll use it as an opportunity to cut their costs as well.

John: I have a question for you, Matt. And, this is really more for the, uh, for Dr. Dev to, uh, respond to in respect. In the aluminum mills – as in steel mills, there's a high level of heat, right? Am I right with that assumption, Matt?

Matt: Yeah.

John: Okay. Dr. Dev, in facilities that the steel mills and aluminum where, you know, where there's a high-level heat. Is this virus survived – do we know yet? Is it, um, does it make any less safe or is it unknown to this point? Because there's a lot of heat in our industry when we're recreating, you know, when we're consuming our products from steel to aluminum to copper, there's a lot of heat involved.

Vip: Yeah.

John: How is that affecting, if it does, affect the virus at this time?

Vip: Hey, John, uh, the biggest issue with this is that all the reports have said that UV light, uh, limits the virus. Uh, the weather patterns, the heat, and the weather patterns, the temperature and so on – weather, uh, limit it, but none of the reports say anything about internal temperature. You know, the body lives at 98.6.

John: Right.

Vip: In a healthy way. Um, people that have fevers, the reason why they have fevers because it's an immune response, the body temperature goes high. Those people still have the virus in them. So, I'm not convinced if, uh, the temperatures around you in a closed space do that. Uh, more importantly, I would ask, are those workers separated far apart? And, are they, do they have protected gear that, that, that limit that spread if they have it? So, I would probably consider that aspect and I'd look at the ages. Um, I don't want to kind of compartmentalize the conversation, but I assume that most of the folks working in these places are middle aged or younger? Uh, just by the nature of the work. So, I assume that they're going to be fairly safer than the folks that are working in certain offices in other areas of, uh – of work.

John: Interesting. All right. Andrew, you, uh – Sean, I'm sorry that we've got to go in order, but I want to get an East Coast steel perspective and movement and what you're seeing over there and, uh, eat, uh, Western Pennsylvania and your area.

Andrew: Sure. Uh, thanks for having me on, John, on the call. Um, you know, what's going on here in just Pennsylvania. Uh, you know, the governor, we've shut down schools, um, starting this week along with other states nearby and, uh, you know, just recently there's, uh, the bars and restaurants have closed – only take out. Um, and essentially non–nonessential businesses are being asked to close, um, or shut their doors. So, salons, uh, gym – uh, gyms, uh, recreational areas and so forth. Um, you know, currently and then in specific counties, Philly and Pittsburgh area, uh, they've asked for other businesses to shut down. Um, we're still open, we're still receiving. Um, you know, uh, my customers, my industrial accounts are still operating right now. Um, we're monitoring them. A couple of them are very tied to automotive, so we're seeing, you know, scheduling, um – if there's any schedule changes out of them. Um, you know, products still moving, we're still able to get trucks out, uh, in the area and just kind of give an update, you know, what we're seeing, you know, prior to the outbreak really hitting here, you know, we had an issue with oil prices and we have a couple mills down in Pittsburgh that are very much tied to oil and gas. Um, so, on Thursday – last Thursday, uh, one of the mills, uh, TMK IPSCO, um, formerly TMK, which is now – they're owned by Tenaris – out of Brazil. Uh, they closed their doors. Um, uh, last Thursday and it's – I don't see them opening back up. Um, they're – they've delayed their orders, sending out the POs, I think, for that reason. Um, so when they do open, you don't have that order to fill, um, at the higher price. Uh, VNM, yesterday, uh, also an oil and gas mill, in Youngstown, Ohio. Uh, they closed their doors, uh, effective today – their gates. They're taking a week off from receiving. I think every mill is really trying to watch their inventory. The flat rolled mills that support the automotive, they've been doing, um, it seems like they've been doing much better. They're still receiving. I'm speaking to Timkin actually this morning in Canton, Ohio. Um, you know, they've had a hard struggle the past couple of months. They're typically 120,000 tons a month they purchase of scrap. Um, they've been idling around 40,000 tons a month. So, a huge reduction. And actually, this month, they bought 80,000 tons and they were, uh, you know, they were planning to purchase another 80,000 in April. Um, they're still planning to run, but obviously you know, that number is going to change and probably be reduced and, you know, everyone's really fearful. What if the virus gets into the mill? What would happen? Um, there's talks that this is a reportable offense by OSHA. How would that change the dynamics at a mill, um, if they have an outbreak and can't run? Um, so right now, um, you know, the automotive mills that are making sheet are still playing the run for next month. Um, as Matt mentioned, you know, I, I really wonder what the hiccup will cause in May. Uh, I can see, may being more affected by this. Uh, if automotive, uh, doesn't start back up after March. Um, surprisingly, talking to some other stainless, um, consumers, um, they're running full-out, uh, in this area. Um, ATI down around Pittsburgh: Uh, they, they can do 17 turns a week. They're running at 15, and they're, asking all of their suppliers for as much scrap as possible. Um, as well as, uh, I've heard, that, I'm gonna not pronounce this right… Down in Alabama – Auto Computo. There's another stainless, uh, consumer. They're looking for blends and looking for material. So, um, so, yeah. I mean, material is still moving. We're still, uh, receiving customers. Um, another recycler in Eerie: they just shut their doors. Uh, today to retail. Um, and it's, you know, we're getting together today to discuss what, you know, revising our plans as needed. Um, but as, as long as manufacturing is going and they need service, you know, we'll be here to service them as much as possible.

John: Outstanding.

Andrew: That’s it.

John: Outstanding report, Andrew. I really appreciate that a lot. All right. Sean – Pacific Northwest. You – areas all around – up in the Portland area. Go.

Sean: Well, you know, I think to – I want to comment on Andrew's point of nonessential business versus essential business, right? We provide a service to our communities, um, to make sure that the sanitation systems have an outlet – that people have an outlet to take their recyclables to, right? As ISRI members, as recyclers, we have a critical role in the communities that we are in. So, for us to stay open is essential. Um, that's our goal at PNW is continue to stay open. And, luckily, flows have been normal. You know, we've seen strong days the last week. Uh, peddler flow has been decent, industrial count flow has been unchanged. Picking up a little bit. I think a lot of the dealers that shift to shredders – that ship to export facilities are starting to feel the heat of getting a product moved, not sitting on inventory. Um, you know, we're able to still make sales. Now, we just made a couple of sales yesterday on copper. I made, Zorba six last week. So, a product is still – demand still there, to Nathan's point. Uh, you know, with containers shortage kind of being low, we might start seeing inventory levels, the different scrap yards increase. But, as you know, Nathan talks about in Southeast Asia and North Asia. They should – that kind of going back to, we'll see those containers pickup and inventories, hopefully, deplete and companies that have it will start to get their cashflow in. Um, it's an interesting time in Oregon and Washington, you know, I – down in San Francisco – John, near you, I mean, you're seeing a lot of companies be affected by shelter in place and have been trying to make sure that they keep their doors open. Um, in Oregon and Washington where the same conversations are happening, our governors are talking about it. The mayor of Portland has a 10-page draft of a shelter-in-place as well. So, it's going to be an interesting time to see how we can be considered essential and continue to keep our doors open. But, where – that's our goal. You know, we want to have normalcy. We want to make sure that our employees, you know, have a job, have a paycheck. You know, also, I think the other point that I heard yesterday from a couple of friends, there's a human aspect to this virus, right? To this pandemic that we're dealing with. All of our employees are pushing themselves to the limits and it's mentally draining for them. You know, we send out a letter of appreciation this morning to every employee of how hard they're working. And, that was from advice from our frie–you know, a couple of friends from yesterday. Um, it's true, you know, it's tremendous the type of community that we have in the scrap world. Um, and to see the support that we're all giving each other, you know, hence this podcast. And, you know, yesterday our – our local chapter held a conference call to talk about what we're doing, uh, to make sure that we support our members locally. So, it's – it's nice to see, you know, I mean, we talk about it, but to see it in action, it's tremendous, so.

John: All right. The mills up in your area, uh… Still buying? What, what? You know.

Sean: Yeah. Mills are still shipping. There's a local mill. Um, most of us know about it. You know, they had a cyberattack and they had – they cut orders, but not directly related to the virus. Um, scrap yards around here, the very few have shut their doors to retail. Most everyone's staying open and those are still buying, cargoes are still moving. You know, we're a bulk exporter, um, of fair scrap. So, you know, we, uh, we're keeping our ear to the ground. Ships are still available. So, I mean, in that regard, there is still some normalcy, um, with mills and, uh, demand.

John: All right. Um, based on time, I'd like to go around the room and, uh, starting with you, Brett… Questions for any of the panelists here or comments for what you've heard?

Brett: No, no. I just encourage everybody to do everything they can to help each other out. Stay, you know, stay involved, stay – keep communicating with each other, um, and, uh, do what you can to, to help each other. I mean, and I think other businesses in your region, right? I mean, your customers, you know, even your quasi competitors. I mean, I take pride in doing a lot of business with a lot of people I compete every day as well. So, I mean, I think that's, that's the biggest thing is just, just lean on each other, help each other out. I mean, we know this is kind of one of them, um, things we didn't see coming, but so is life. We now just got to figure out how to get through it and I don't really have any questions for anybody other than, you know, just keep us posted, what's going on in your area and hopefully, you know, this thing, at least we get some quasi back to normal here in the next 30 to 60 days. That's kinda what I'm – what I'm hoping for and what I'm shooting for. Um, it's, it's kinda nice. My commute to work’s been significantly shorter now, so now less people on the road. Um, yeah. Like I said, try and find the good in the shit and figure it out.

John: There you go, Brett. Well, thank you for your input today. Matt Kripke. Comments? Questions?

Matt: Yeah, I guess I'm curious. We've moved to, um, you know, in our Tennessee location where eight people work, we – no one is working in that office. We are all working remotely. Our Ford office: only remote. Uh, here in Toledo, we have a skeleton crew here. I already told you about what we did in, uh, the metal processing area – down to nine people out there. In the office, we only have, uh, seven right now. Uh, normally closer to, uh, 20 to 25. So, we are allowing people to work remotely. And, I realize the rest of you are processing facilities, but you do have payable clerks. You do have controllers. Um, are those people working remotely yet? And, if so, what are you doing? How are you coordinating that?

John: Well, at Sierra – to jump in, uh, all our sales force, um, our next two weeks: basically self-quarantining at home. We've had people that were at ConExpo last week. Everybody was there in self-quarantine. Um, pretty much everybody's gone stir crazy. They want to come back to the office. You know, Kern County has one official case, uh, of COVID-19. Um, they are working from home. Uh, you know, we provided, uh, laborers are here. Um, and, you know, we're in a unique place because we don't have the outbreak, okay? And, that's what we're doing. Nathan, to you, uh, respond to Matt’s, uh, inquiry.

Nathan: Re–re–Can you repeat? I didn't hear you.

John: Well, wants to know more what's going on with the, uh, working remotely is, you know…

Nathan: Oh, working remotely? Yeah, we – like you, we are looking at this, really, just as a matter of probability. So, in any environment where we can work from home, that's what we're doing in environments where we are not able to do that. Well, obviously those that are operative scales and processing, we are staggering work, uh, work schedules. So, rather than having 100% of the employed group at the yard in the scale house at the same time, they're coming in to alternate and we're doing that to the extent that we can still keep the business operating. And again, does that guarantee the, uh, the ability for someone not to contract or to not spread? No, but if we're looking at it scientifically and just trying to go by probability, we're just trying to lower that risk in any way that we can.

John: Sean. You kind of answered that a little bit already, but how many people you got working remotely versus just staying home?

Sean: Very few people are working remotely right now. Our sales staff: we've asked to stay home, um, but you know, pretty much everyone else is back in the office and, you know, we're practicing social distancing as much as we can. Having them stay in their office, not going around. Um, we actually have it each break room, an employee that's been designated to continue to make sure every area is sanitized and cleaned. And, then the scale houses stay to your spot. We've cut off all contacted a public – well, we've tried to cut off all, contacted the public, putting in safeguards and procedures. Uh, transfer tickets, those are being emailed, things that are being sent by truck or transfers, you know, operating five locations. We have quite a bit. We've tried we to put actions in place to protect them, but very limited our, uh, working remotely right now cause it just wouldn't be operationally, um, effective or efficient. So, unfortunately.

John: All right. Drew?

Andrew: A lot of the same measures. Um, we're still accepting the retail, as I said, but they're not coming into the office, were collecting the information at the scale, keeping them in their car, um, handling their metals, um, and then handing a check outside or, um, but not in the office. Uh, drivers, same thing. We do everything electronically. Um, they have iPads so they can get their dispatches. Um, you know, communicating them not to go into account offices, not coming into our office. Um, and then, you know, wiping down their cab at the start and end of the day. And, the same things for our crane operators. Um, outside of that with, uh, yeah, break room, no more than four, you know, employees at a time. We're trying to encourage them to, you know, eat in their car. Um, and just, you know, practice the social distancing, of course, the, the hand washing and all that. Um, you know, one question I had for the doctor: Um, I saw a report this morning that – and I wonder if you could speak to it. I was just seeing a higher case of younger adults being admitted for the, uh, COVID-19 and having – I don't know if they had respiratory issues, but more of them being hospitalized. And, I'm curious if there's any facts or figures on that?

Vip: Yeah. Uh, so, and that is true. You know, uh, the 20 to 40-year range, you're seeing, uh, an uptick a little bit in that and the – simply because we have more availability of the test kits.

Andrew: Okay.

Vip: And so, we have availability of test kits, the best thing to do is to do one of two things: uh, as soon as you get tested, quarantine yourself. If you show signs and symptoms, see your doctor and then get hospitalized, so then you can get treated appropriately. And that's the key is if you have any kind of respiratory system, uh, symptoms get treated quickly. So, then you prevent that lung from scarring down and developing a pneumonia-type process. Most of them recovered, by the way, most of these 20-year olds, 20 to 44-year-olds, uh, are almost all recovered. Good.

Brett: Can I ask you a quick question real quick?

Vip: Sure.

John: Go ahead, Brett.

Brett: Do you think that as more tests become available and the speed at which you can be tested, more people will realize that you've either had it, have it, whatever? Um, and then obviously the number of cases will go up, but then people will start to realize the actual mortality rate or the thickness level? I mean, so basically, it increases the total cases, but it also reduces the percentage. Um, which will kind of alleviate some of the factor side of it?

Vip: No, you're absolutely right. And remember, gentlemen, we're not – what we're going to see is nothing different than the Flu, right? The common Flu we hear about and all the deaths that happened. Um, the Flu still happens every year. And, I think that may, that may be something what we get used to. It’s just that we're going to know how to treat ourselves with this. And, and you're right on Brett. That's, uh, I think that's a fairly accurate assumption.

John: All right, gentlemen, listen, uh, we're got time constraints. People have to jump. I want to thank everybody for being on this call. Um, you know, this is, uh, I think it's informative – interesting about the autos. And Andrew, great report. Matt, everybody: great reports. Sean, uh, Nathan, Brett. I think this is very informative. I mean, there's still movement, there's still action. Our industry is still supporting the infrastructure of the world by our products being made into, you know, new cars, new bridges, new copper outlets for electrical, et cetera, et cetera, et cetera, and manufacturing for autos and what have you. So, everybody, I want to thank you. Matt, you want to end it? You love ending it.

Matt: This has been Pile of Scrap with John Sacco.

John: Thanks, Matt. Thanks, everybody.

Conclusion: This has been a Sierra International Machinery original audio series. Thanks for listening. Please share this podcast and make sure to subscribe.

The Pile of Scrap Podcast is available on Apple Podcasts, Spotify, and Google Play. The Podcast episode videos are available on YouTube. Be sure to Subscribe, Rate, and Review Pile of Scrap.